At its Auersthal extraction station OMV relies on a technology new to E&P Austria for processing crude oil and the oil-water separation which this requires.

VTU Engineering planned and implemented a project for the separation of oil and water which centers on hydrocyclones. OMV's Exploration & Production (E&P) business segment has a strong base for crude oil extraction in Romania and Austria and is continually expanding its international portfolio. At the end of 2014 OMV had approximately 1.1 billion oil-equivalent barrels of proven reserves and in 2014 produced on average 309 oil-equivalent kilobarrels per day. Some of this quantity is produced in the fields around the Auersthal extraction station and is brought there for separation into crude oil, natural gas and water.

Doubling of capacity and increasing quality

During a project lasting around three years, VTUEngineering was entrusted with the task of doubling the water treatment capacity in the Auersthal extraction station while at the same time reducing the remaining oil content in the water. As a result, based on a feasibility study on basic and detail engineering, a system with several oil-water-gas separation stages was integrated in an existing operation.

Station entrance and slug catchers

The delivery lines (oil-water-gas mixture) coming from the field are first routed to four so-called slug catchers at the station entrance. These are upright vessels which are used to compensate fluctuations in delivery in the pipelines and ensure continuous feeding of the downstream separation steps. A first separation of the gas phase also takes place.

Separators

The uniform oil-water mixture from the slug catchers is automatically routed into the seven separators. Due to a certain residence time, 98 percent of the oil is separated in this step. The oil runs over a weir into a dedicated chamber integrated in the separator and is then collected in tanks for treatment later. The water is subjected to an additional separation step as its oil content downstream of the separators is still too high to be re-used.

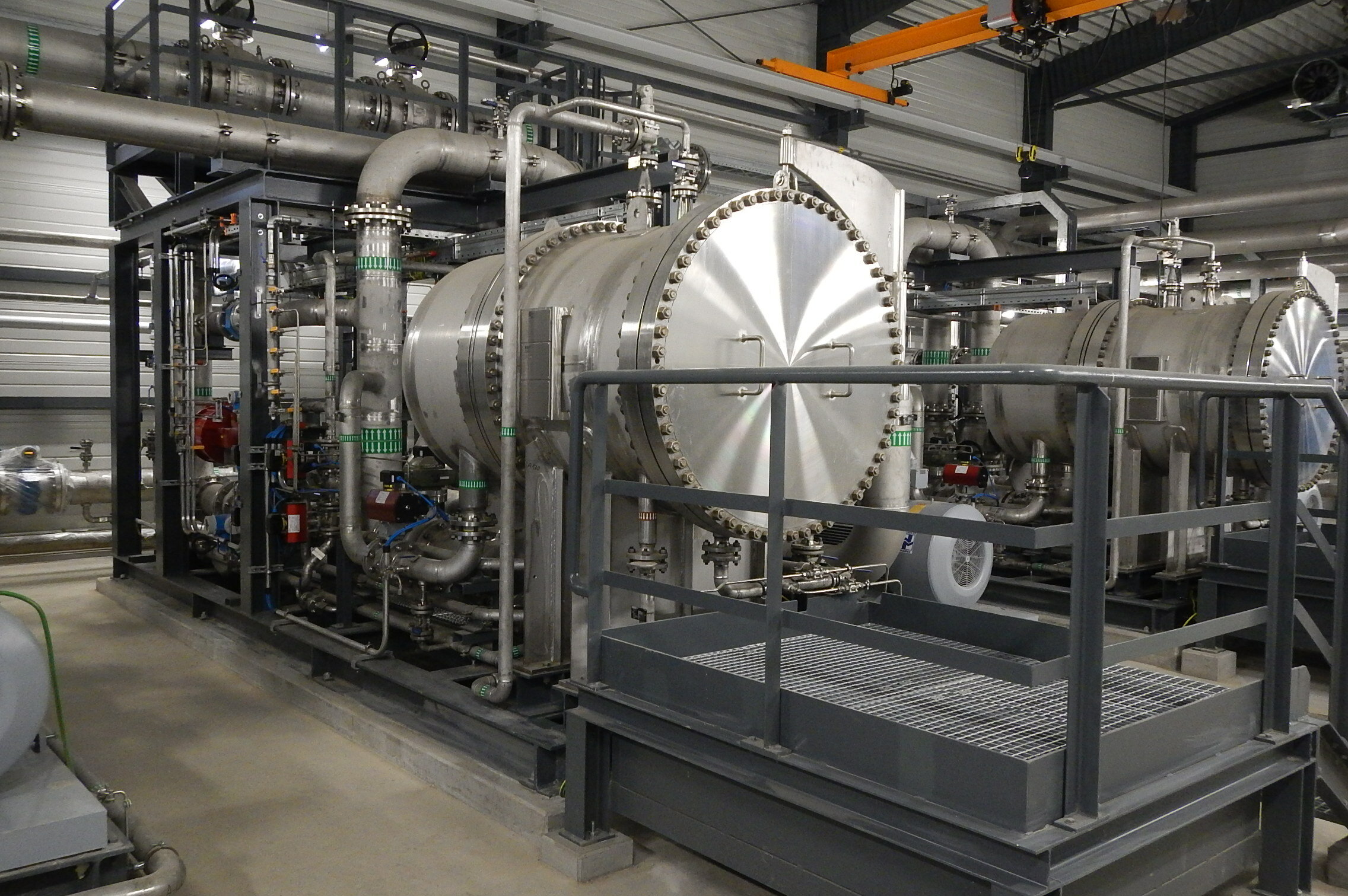

Hydrocyclones and station exit

This additional separation step – the hydrocyclone – is a technology which has not previously been used in Austria for oil-water separation in the oil industry. The three hydrocyclone skids, which in turn consist of several hundred individual hydrocyclones, follow a preliminary pressure increase. The oil content in the water is reduced to approximately one-fifth of the input value by means of centrifugal force. While the oil phase is collected again in the tanks already mentioned, the purified water is fed back to the fields via pumps at the station exit to maintain pressure.