VTU Engineering was commissioned to carry out the general planning of a new building at Roche Diagnostics in Rotkreuz (CH)

Measures to ensure maximum efficiency in the commissioning process also played a major part here.The Rotkreuz site of Roche Diagnostics AG in the Swiss Canton of Zug is one of the world's leading development and production centres for leading-edge instrumentation and software systems for in-vitro diagnostics. Roche is currently constructing a new plant in Rotkreuz for the production of reagents, sensors and instruments for blood gas, electrolyte and metabolite analysis systems. Production of the analysis systems is currently still taking place at the Roche site in Graz, but will be relocated to Rotkreuz by the end of 2013.

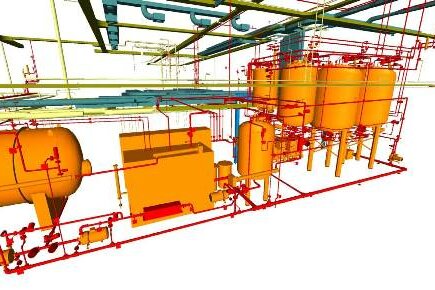

VTU Engineering had already been working as an engineering partner of Roche Diagnostics in Graz for a number of years and also carried out the planning for the existing plant. With substantial project management experience and expertise, VTU had the ideal credentials for the product transfer required for the relocation of development and production. VTU Engineering was entrusted by Roche with the general planning for the reagents operation for the construction of the new plant in Rotkreuz. VTU commissioned partners in Switzerland to handle the architecture, electrical design, HVAC and structural surveying. In addition to the general planning, the services provided by VTU also include technical planning of the process plant, creating URS and P&I diagrams, EI&C planning and automation, as well as 3D planning with isometric drawings. Furthermore, VTU is responsible for the provision of the main equipment, technical construction management and commissioning.

VTU Engineering carried out the technical process planning using the ComosPT software. This simplified updating datasheets and lists, as the same data material is accessed for all documents. A modular plant design was used to increase efficiency and simplify the production of functional descriptions. This allowed the individual functions to be copied into the respective units. As a result, complexity and susceptibility to errors are significantly reduced in engineering, in drafting the functional description, in programming, in test outlay and in the forthcoming commissioning. In addition to the general planning project, VTU Engineering was also tasked with managing the commissioning of the entire transfer project. Its responsibilities include the entire coordination of the commissioning and the production of the commissioning schedule, including its approval with all parties involved in the project, starting with the three sub-projects for the reagents, sensors and instruments, and including production and qualification, and involving all companies working on the project.